Steel information

I often get asked what is the best knife. There is a myriad of factors that make up a good knife. Steel properties, blade geometry, handle geometry, heat treat etc. First and foremost, you have to have an idea what will you be using the knife for. What will be its main purpose - carving, slicing, batoning, chopping, EDC?

One major factor to a good knife is the steel it's made of and how the steels properties match what you expect from the knife.

Below are short descriptions and charts for all the knife steels used in the knives that we sell in our webshop. Hopefully this will help you find the knife that best fits your needs.

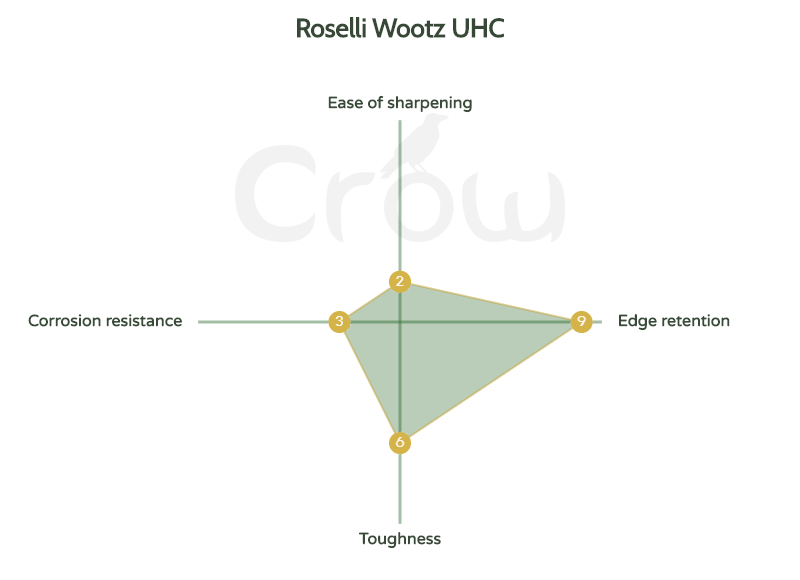

Roselli Wootz UHC

This is Roselli’s version of Wootz steel which originates from India some 2000 years back. The effective hardness of these blades is 64-66 HRC without losing its toughness. Wootz UHC steel has superb edge retention but that comes at the cost of ease of sharpening. When buying a Wootz UHC steel blade one must have a diamond sharpener as sharpening stones can do the job, but it is labour intensive. Being a carbon steel, it needs to be properly dried after use.

| Ease of sharpening: | 2/10 |

| Edge retention: |

9/10 |

| Toughness: | 6/10 |

| Corrosion resistance: | 3/10 |

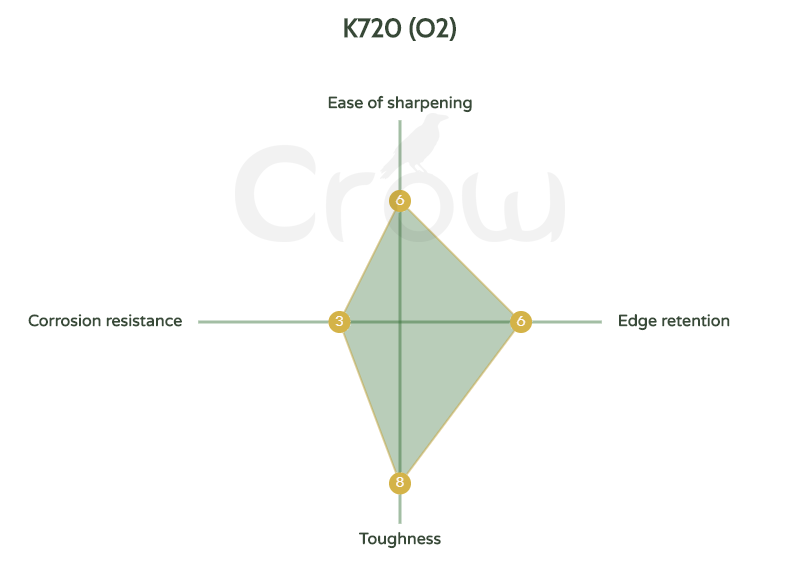

K720 (O2)

K720 (O2) is a carbon steel which is fairly easy to sharpen and takes a great edge. It has good edge retention and is a tough steel. This makes it a good choice for bushcrafting where you need a good all-round performing blade which can take batoning and is also able to keep an edge when carving. When the blade gets a bit dull, it is easy to strop it back to shaving sharp. The biggest con to K720 is its low corrosion resistance so you should dry your blade after use and oil it occasionally.

| Ease of sharpening: | 6/10 |

| Edge retention: | 6/10 |

| Toughness: | 8/10 |

| Corrosion resistance: | 3/10 |

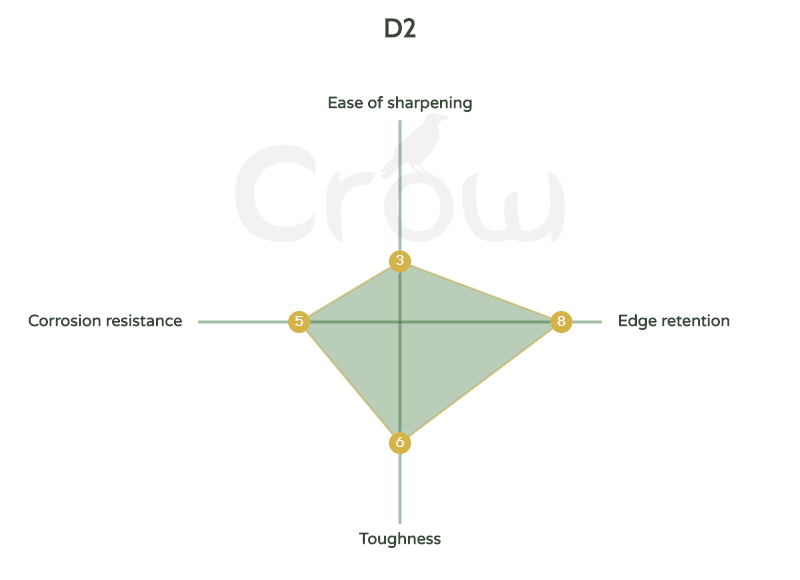

D2 (AISI D2; DIN 1.2379)

By German DIN standard the D2’s chemical equivalent is 1.2379 steel.

D2 is a good all-round blade steel which dates to the 1940’s.

While toughness and edge retention are above average, the D2 blades are harder to sharpen than most steels and due to not being stainless it takes more attention and care to keep the blade in good condition. When you have experience with sharpening then a D2 is a reliable choice for a knife.

D2 can be considered semi-stainless steel with its 12% chromium content (13% to be considered stainless) and should be occasionally oiled to prevent corrosion.

| Ease of sharpening: | 3/10 |

| Edge retention: | 8/10 |

| Toughness: | 6/10 |

| Corrosion resistance: | 5/10 |

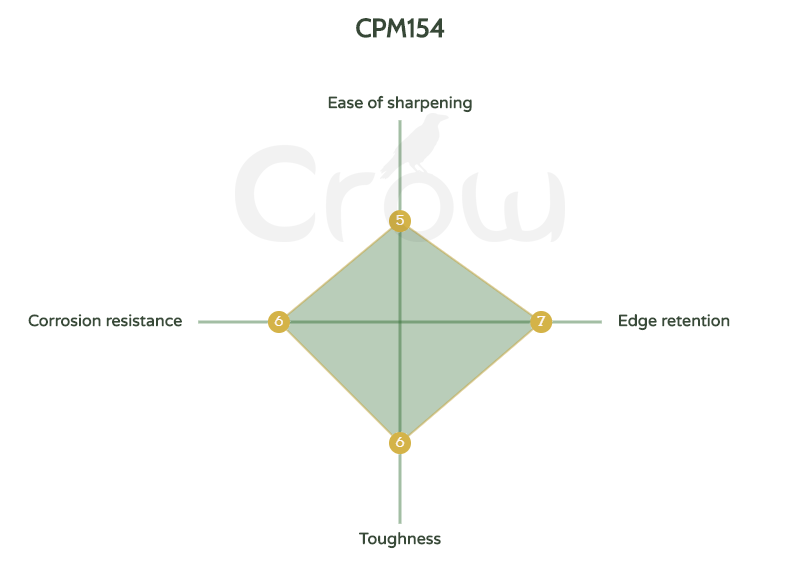

CPM 154

CPM 154 is a great stainless blade steel for knives. It is moderately easy to sharpen and holds its edge well, it has good corrosion resistance and toughness. CPM 154 has the same chemical composition as 154CM, but the production processes are different. CPM 154 is produced by Crucible Industries through Crucible Particle Metallurgy process about which you can read more about HERE. Shortly the molten metal is blasted through a small nozzle which turns the metal into fine mist which solidifies rapidly and when bonded and compacted, retains a very fine structure which gives the steel its superior mechanical properties compared to 154CM.

| Ease of sharpening: | 5/10 |

| Edge retention: | 7/10 |

| Toughness: | 6/10 |

| Corrosion resistance:: | 6/10 |

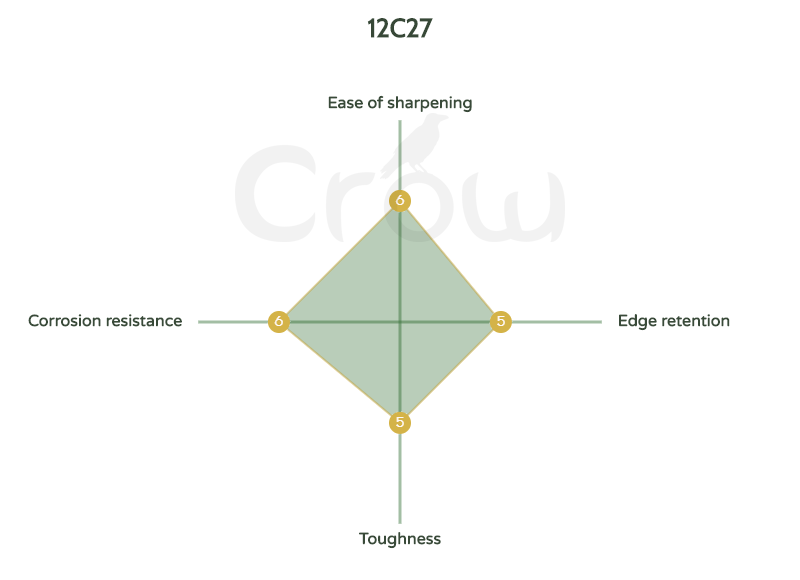

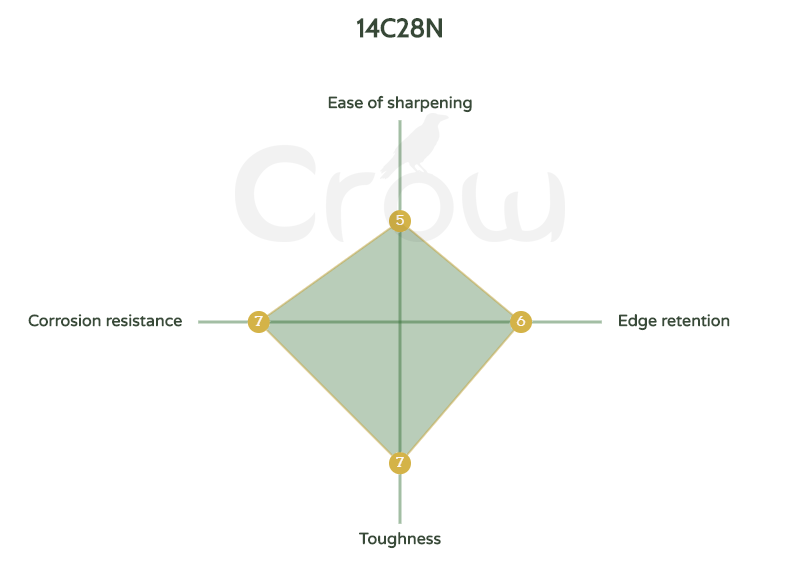

Sandvik steels 12C27 and 14C28N

Stainless steels produced in Sweden by Sandvik. 12C27 is a good all-round blade steel – easy to sharpen and strop, holds a decent edge and is corrosion resistant. It is a good and popular steel for smaller knives. For bigger knives, 14C28N – an upgrade of 12C27 – is more suited as it can be hardened to a higher HRC value without losing its toughness. In most steels, carbon is used to increase hardness but 14C28N uses nitrogen. This allows for higher hardness without compromising corrosion resistance. All that makes the 14C28N a superior steel compared to 12C27 when it comes to tougher tasks such as batoning – better edge retention without compromising toughness or corrosion resistance.

12C27

| Ease of sharpening: | 6/10 |

| Edge retention: | 5/10 |

| Toughness: | 5/10 |

| Corrosion resistance: | 6/10 |

14C28N

| Ease of sharpening: | 5/10 |

| Edge retention: | 6/10 |

| Toughness: | 7/10 |

| Corrosion resistance: | 7/10 |

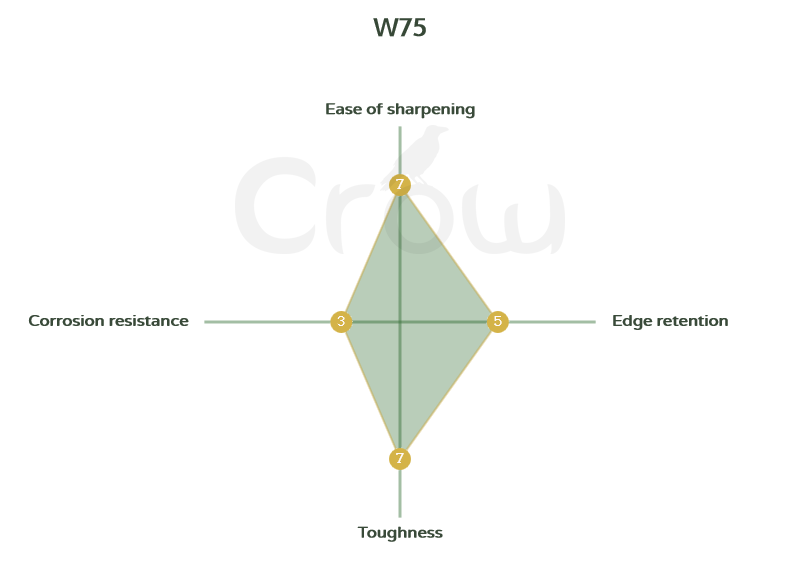

W75

Thyssen-Krupp W75 is a carbon steel with around 0,8% carbon content. W75 is used in Roselli’s carbon steel knife series. W75 blades are easy to sharpen on stone sharpeners and mostly it only takes a few strokes on a strop to get it sharp again. Toughness and edge retention are good but being a carbon steel, it rusts fairly easy. Tough, easy to sharpen, holds an edge well and as long as you take care of your blade by not letting it rust, it will be a reliable blade for a long time.

| Ease of sharpening: |

7/10 |

| Edge retention: | 5/10 |

| Toughness: | 7/10 |

| Corrosion resistance: | 3/10 |

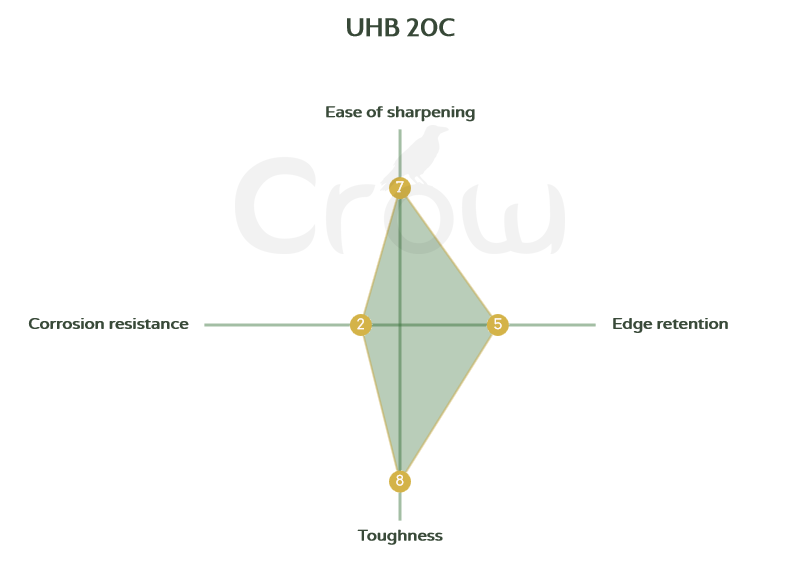

UHB 20C

UHB 20C is Böhler-Uddeholm’s equivalent of 1095 steel. UHB 20C, containing less sulfur and phosphorus, which are often regarded as impurities, is considered a cleaner alloy. UHB 20C is easy to sharpen and achieving a razor-sharp edge is relatively easy. Edge retention is also decent. The biggest pro, of UHB 20C, is its toughness, it holds up to batoning and prying very well. The biggest con is the low corrosion resistance, and thus it is not suitable for wet and humid conditions. Under normal conditions, proper drying is enough to keep the blade from rusting.

| Ease of sharpening: |

7/10 |

| Edge retention: | 5/10 |

| Toughness: | 7/10 |

| Corrosion resistance: | 3/10 |

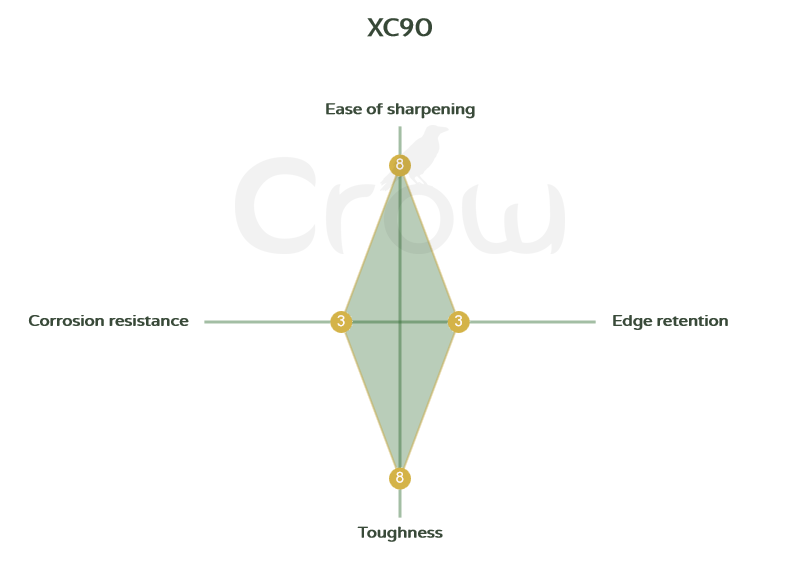

XC90

XC90 is comparable to AISI 1086 steel. One can say that XC90 is a “simple” steel – it both dulls and sharpens easily; all it mostly takes is a proper stropping to get a blade sharp again. It is also a strong steel which can withstand prying and bending, blades usually roll rather than chip. Being a carbon steel, it rusts easily. It also should be at the top of the list for any patina fans out there, XC90 develops a nice patina and it doesn’t take much time.

| Ease of sharpening: |

8/10 |

| Edge retention: | 3/10 |

| Toughness: | 8/10 |

| Corrosion resistance: | 3/10 |

Knife steel equivalents

| Standard | Bohler | |

| DIN.EN | AISI | |

| 1.1203 | 1055 | - |

| 1.1545 | W110 | K990 |

| 1.2083 | 420 | M310 |

| 1.2085 | 420+S | M304 |

| 1.2162 | - | M100 |

| 1.2311 | P20 | W330 |

| 1.2312 | P20+S | M200 |

| 1.2316 | - | M300 |

| 1.2344 | H13 | W302 |

| 1.2363 | A2 | K305 |

| 1.2367 | - | W303 |

| 1.2379 | D2 | K110 |

| 1.2436 | - | K107 |

| 1.2510 | O1 | K460 |

| 1.2550 | S1 | K455 |

| 1.2714 | L6 | W500 |

| 1.2738 | P20+Ni | - |

| 1.2767 | - | K600 |

| 1.2842 | O2 | K720 |